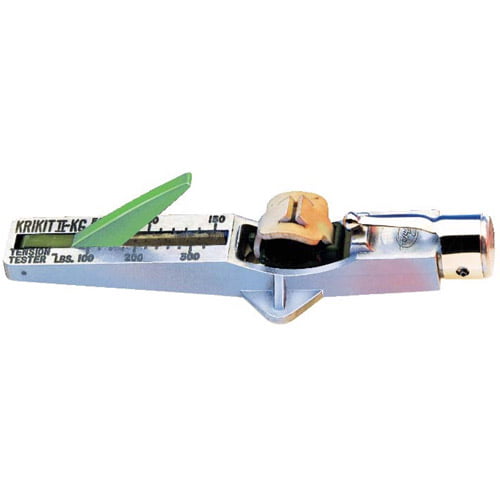

The force should be between the minimum and maximum shown. Compare the force you have applied with the values given in the tables below. Remove the tension checker and read the force applied from the bottom of the small “O” ring on the deflection force scale. Apply a force on the plunger and perpendicular to the belt span until the bottom of the large “O” ring is even with the top of the adjacent (next) belt or with the bottom of a straight edge laid across the outside diameters of the V-belt sheaves.

Place the tension checker squarely on one belt at the center of the belt span. Set the small “O” ring on the deflection force scale to zero. Position bottom of the large “O” ring on the span scale at the measured belt span. Never apply belt dressing as this will damage the belt and cause early failure. Un- der-tensioned belt drives often produce audible squeal noise. Make V-drive inspection on a periodic basis. Keep belts free of foreign material which may cause slip. Over tensioning shortens belt and bearing life.

Check after jog start or 1-3 minutes of operation, at 8 hours, 24 hours, 100 hours and periodically thereafter are recommended. Check tension frequently during the first 24 hours of operation. Ideal tension is the lowest tension at which the belt will not slip under peak load conditions. BELT TENSION CHECKER TENSIONING V-BELT DRIVES WITH A BROWNING TENSION CHECKER General rules of tensioning. © Emerson Power Transmission Manufacturing, L.

0 kommentar(er)

0 kommentar(er)